Description

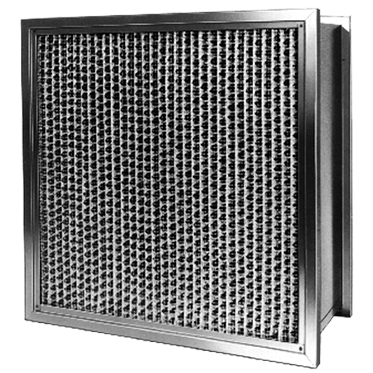

The DuraCel ® Filter Features Advanced Design for Superior Performance

- High performance in both efficiency and dust holding capacity

- All metal cell sides

- Flanged headers

- Welded face guards on air entering and air leaving sides

- Light weight

- Temperature limits: up to 302 ̊F/150 ̊C intermittent; 248 ̊F/120 ̊C continuous

- Low average operating resistance

- Longer life than standard filters

- Less filter changeout

The DuraCel is a heavy duty, high efficiency filter unit developed especially for the rotating machinery industry. It is designed to withstand the rigors of centrifugal compressors, gas turbines and engines where severe surging or pulsations occur.

Construction

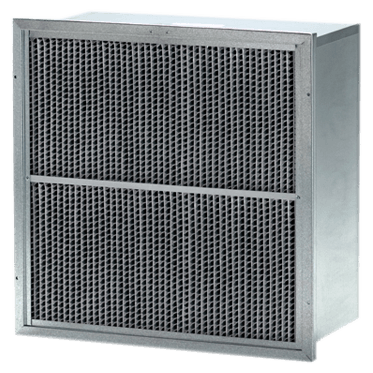

The DuraCel filter is constructed of all metal cell sides with spot welded face guards and header flanges on the air entering and air leaving sides. The DuraCel filter is available in four styles, XL-60, XL-60N, XL-90 and XL-90N.

The media pack of the DuraCel filter consists of a new high efficiency glass media of graduated density that ensures full depth loading. The filter media is folded between aluminum separators in a pleated design. The separators are spot glued to the adjoining media panel and then the leading edge of the separator is placed in the inside of the media fold. This unique construction feature prevents the separators from moving and puncturing the media.

Features & Benefits

- The DuraCel gas turbine filter consists of a high-efficiency glass media supported by corrugated metal separators that ensures optimum spacing and full loading of the filter media.

- This heavy-duty filter is constructed with metal sides, welded face guards and header flanges.

- The lower pressure drop results in reduced operational expenditure.

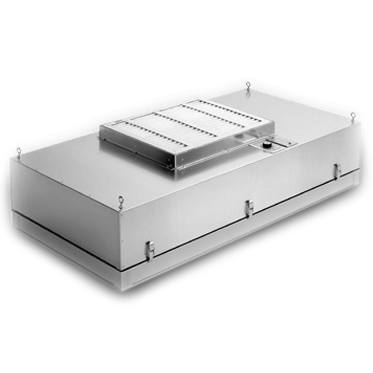

- Available in a range of efficiency grades and in single or double header configurations to meet the system requirements of the operator.