Description

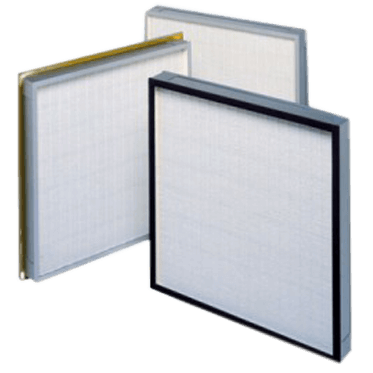

AmAir 300X filters are constructed with AAF’s totally unitized, double wall, die-cut box, beverage board frame. The media pack is bonded inside the frame at all points of contact. AmAir 300X filters are built Dd rugged tor durability and reliability under tough service conditions. The AmAir 300X filter is a MERV 7 in accordance with ASHRAE Standard 52.2.

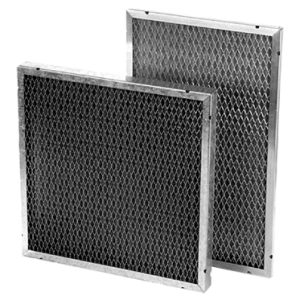

AmAir HT High Temperature Filters

The AmAir HT filter is designed for applications with continuous operating temperatures up to 500F (2600). The frame is an aluminized steel U-channel, with the media pack bonded to the inside on all four edges. An expanded aluminized steel faceguard is spot welded inside the frame on the air-leaving side to retain the media pack at elevated temperatures. AmAir HT filters are made with microglass media, and is MERV 8 in accordance with ASHRAE Standard 52.2

Superior Strength

AmAir 300X filters are extremely strong and durable, with all components rigidly bonded into a totally unitized construction. The filters will not rack or deteriorate under normal operating conditions, including high moisture applications.

An expanded metal grid laminated to the air leaving side of the media creates more consistent pleat shape and maintains uniform pleat spacing. Expanded metal also increases the stability of the pleat pack, reducing media flutter during operation.

The media pack support retainers, which are an integral part of the frame, are bonded to the pleats on both the air entering and the air leaving sides. This increases rigidity and also helps maintain proper spacing between pleats for maximum dust holding capacity while minimizing resistance.