Description

Media Manufacturing

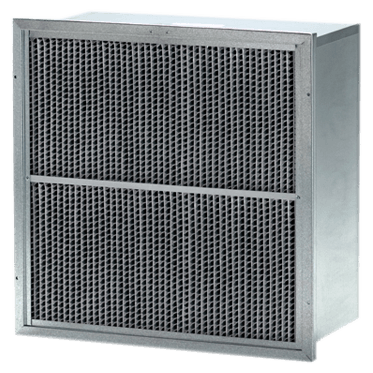

The ability to conduct in-house research and development on filter media led AAF Flanders to the exclusive development of the unique DimplePleat filter. Filter media is formulated from all-glass microfibers, wet-laid on AAF Flanders’ dedicated papermaking process. Binding and waterproofing agents are drawn completely through the media while in the wet stage, ensuring maximum tensile strength and protection from humidity. The media is constantly monitored by process controls to ensure correct physical properties.

HEPA & ULPA Efficiency Testing

Each HEPA and ULPA filter is tested for efficiency and resistance by Dual Laser Spectrometer. The spectrometer samples simultaneously on the upstream and downstream sides of the filter to determine the percentage of penetration. AAF Flanders’ standard test challenge is an aerosol of polystyrene latex (PSL) spheres. The laser instrument detects the size of each penetrating sphere in seven particle size classes from 0.07μm to 1.0μm. Resistance readings are taken according to volumetric parameters (i.e. – 100 CFM per ft2 of media face area) and are expressed in inches of water gauge.