Description

Now Better Than Ever

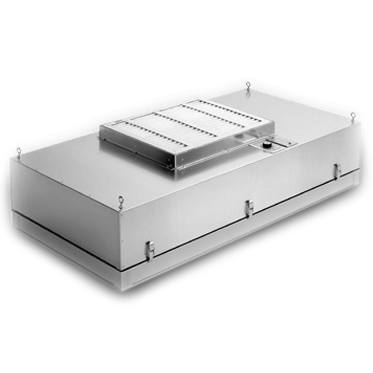

Today’s DriPak 2000 filter features a unique, ultrasonically-welded pocket configuration that guarantees complete pocket inflation and eliminates crowding or leakage. Reinforced pocket support frames eliminate flexing or buckling, even in a turbulent operating environment.

IAQ Engineered

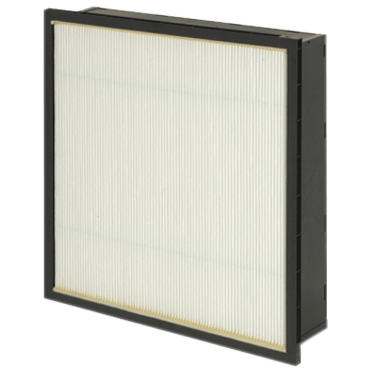

The DriPak 2000 filter is available in three efficiencies, MERV 15, MERV 14, and MERV 12 to meet your need for cleaner air and improve Indoor Air Quality (IAQ)

The DriPak 2000 filter is made from layered, meltblown synthetic media, protected by a scrim on the air-leaving side. Layering the media provides both a high-efficiency final filter layer that effectively filters fine particulate, and an integral lofted prefilter layer that captures larger particulate. Meltblown synthetic media is stronger than fiberglass, and is both non-shedding and water-resistant.

Designed for Performance

DriPak 2000 filters employ a sturdy pocket design that includes ultrasonic welding to ensure leak-free pockets. Interlocked support frames attached to the pockets prevent flexing and buckling during full inflation. The double U-shaped, reinforced header forms a solid container for the pocket support frames.

Ultrasonically-Welded Pocket Construction

The DriPak 2000 filter ultrasonically-welded pocket construction features ribbons of fabric sealed inside the pockets to create aerodynamic channels. This eliminates the needle holes associated with span stitching. The contoured shape of the pocket allows full inflation without crowding or restricting airflow, to ensure full media utilization and long service life.