Description

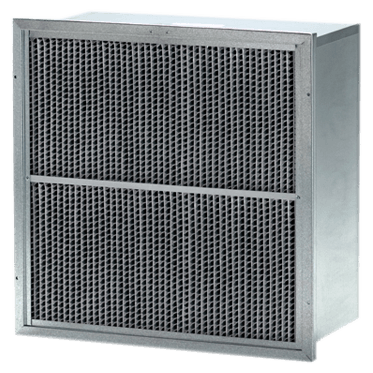

Energy Conservation=Energy Savings

AAF Flanders’ eFRM pleat pack resistance is up to 50% lower than conventional micro fiberglass media, a significant factor contributing to a great reduction in fan energy consumption. AAF Flanders’ eFRM membrane media, combined with tapered aluminum separators, optimizes pleat pack resistance. With a reduction in fan energy consumption, overall energy savings can be realized.

Perfect Filter Media

Compared with micro fiberglass media, eFRM membrane media provides superior benefits, including inert chemical properties, more uniform fiber distribution, smaller fiber diameters, and smaller pore size. As a result, reduced resistance and higher filtration performance provide substantial energy savings.

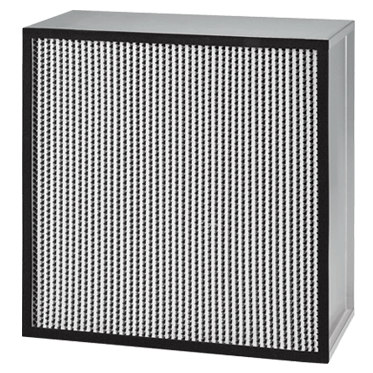

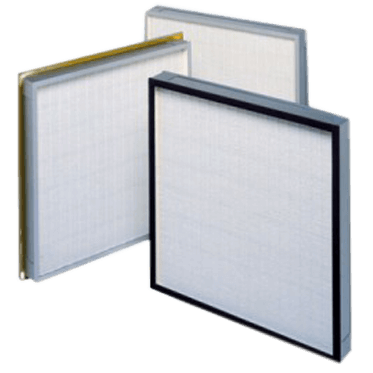

State-of-the-Art Design

Designed to combine maximum efficiency with lowest pressure drop, the MEGAcel I eFRM filter media pack is available in different depths, sizes, and cell side configurations, allowing for a variety of application requirements, including:

- Healthcare

- Food Processing

- Pharmaceutical

- Laboratory

- Electronic

- Semiconductor

eFRM Membrane Media Developed by AAF Flanders Engineers

Groundbreaking eFRM technology was engineered by AAF Flanders’ research and design teams. Media production, testing, and packaging are all performed in AAF Flanders’ ultra-modern ISO Certified controlled environment, eliminating the potential for contamination of the filter during manufacturing.