Description

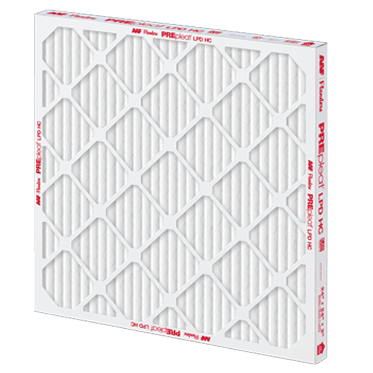

A Perfect Filter Media

Compared to micro fiberglass media, AAF Flanders’ ePTFE media provides superior benefits, including inert chemical properties and reduced resistance. Achieved through a more uniform fiber distribution, smaller fiber distribution, smaller fiber diameter, and smaller pore size, ePTFE media generates substantial energy savings while delivering the required filtration performance.[/vc_column_text][vc_column_text woodmart_inline=”no” text_larger=”no”]

Chemical Advantages of AAF Flanders ePTFE Media

Negligible Off-Gassing

AAF Flanders’ ePTFE media is naturally boron-free and the materials of construction have been chosen to meet the most stringent of off-gassing requirements. The off-gassing impurities are significantly reduced compared to micro fiberglass.

High Corrosion Resistance

ePTFE media is chemically inert and resistant to highly corrosive agents, including alkaline, acid, and organic substances- all of which can be found in semiconductor manufacturing processes.

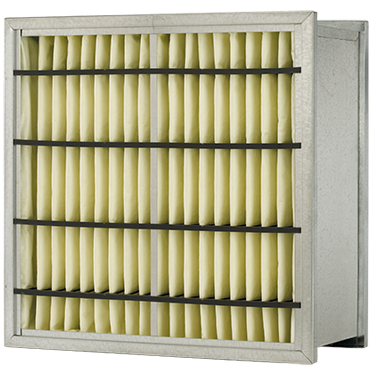

Sturdy Construction

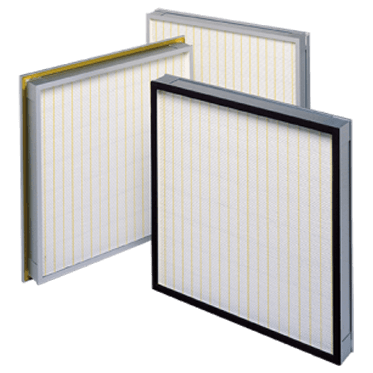

Tooling environments often produce harmful and corrosive by-products. The MEGAcel® II ePTFE filter is extremely resistant to these harsh conditions, and also offers superior efficiency and pressure drop characteristics. Manufactured with a proprietary, high-quality ePTFE media, the MEGAcel® II ePTFE filter is hydrophobic and meets the requirements of UL900. The media pack is permanently attached to an anodized extruded aluminum frame using a urethane adhesive

Superior Water Resistance

AAF Flanders’ ePTFE media is hydrophobic and provides superior water resistance in comparison with micro fiberglass and low boron micro fiberglass media.