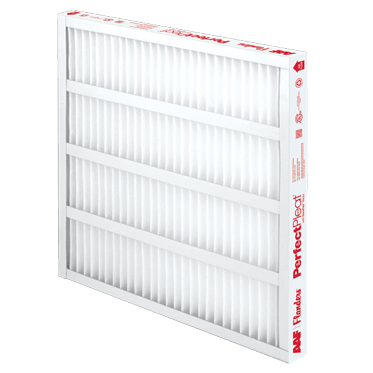

Description

The PerfectPleat HC M8 filter has approximately 25% more media than our standard capacity filter, and is ideal for applications where pleated filters are currently in use and higher performance is desired. It has an initial MERV 8 rating respectively, but the efficiency increases when dust holding begins. PerfectPleat HC M8 filters have distinctive self-supporting characteristics that allow a pleating pattern, which promotes airflow and maximizes dust holding capacity (DHC). Lower pressure drop and higher DHC translate to reductions in energy consumption and operating costs.

DuraFlex® Media – Patented Media Design

Uniform-size virgin fibers are assembled in closely controlled blends to create a media that is both self-supporting and consistent in performance. When pleated, DuraFlex media will hold its shape without the wire support characteristic of conventional pleated filters. That means no potential for the formation of rust and safer handling. With the superior resiliency of DuraFlex media and no need for wire support, PerfectPleat HC M8 filters can sustain significant abuse and maintain their shape and pleat spacing. The absence of wire also makes the filter totally incinerable, which can simplify disposal.

Superior Design and Construction

The perimeter frame is constructed from the highest wet-strength 28 pt. beverage carrier board, securely bonded to the media pack. The 1″ model employs three supporting straps on the air-entering and air-leaving sides of the filter to control pleat spacing and support the media pack in the perimeter frame.

Support straps on the air-entering side are used in combination with a triple layer tri-ply support bar on the air-leaving side of the 2″ model to provide additional strength. The support straps and tri-ply support bar ensure integrity against turbulent airflow. The 2″ filter resists crushing and abuse, and provides excellent lateral stability for installation in side-access systems.

The 4″ model utilizes a two-piece die-cut frame with integral pleat spacers on the air-leaving side. Pleat spacing is controlled by straps bonded to the air-entering side and the multiple rows of pleat spacers on the air-leaving side. The pleat spacers also ensure that the pleats remain open during use, maximizing filter life.