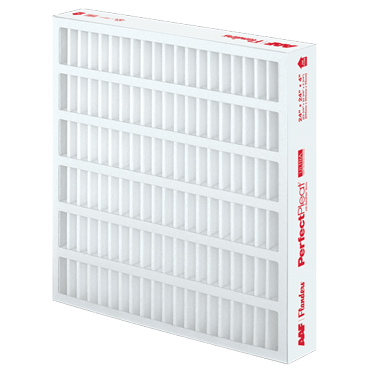

Description

Designed For Superior Performance

High Capacity, Low Resistance Operation

The DuraVee filter derives its name from the innovative construction design consisting of six mini-pleat media packs assembled into a series of three V-banks. Setting the mini-pleat packs in a multiple V-bank arrangement substantially increases the amount of media contained in the filter by up to 40% more than conventional rigid filter packs. This results in a greater airflow capacity, low resistance, and high dust holding capacity.

Dual Density Media

The DuraVee media is manufactured with two layers of microglass paper fibers: coarser fibers on the air entering side and finer fibers on the air leaving side. The progressive density produced by this process ensures a full depth loading of dirt, providing a high dust loading capacity which extends the life of the filter.

Rigid Construction Maintains Media Pack Integrity

The mini-pleat media packs are bonded inside the cell sides with a urethane sealant, forming a completely unitized, rigid filter that does not rack and resists damage during shipping and handling. The bonded media packs also prevent bypass leakage.

Low Profile Thermoplastic Separators

Separators made from continuous beads of thermoplastic material maintain uniform spacing between pleats to allow optimal airflow into and through the filter with minimum resistance. The low profile beads of thermoplastic create a media pack with minimum pleat spacing. The separators ensure a large effective area for low resistance and high dust holding capacity

Operating Temperature

All DuraVee filter elements can operate continuously at temperatures up to 176 ̊F.

Water Repellent Media

The media is water repellent and can withstand intermittent exposure to free moisture in the airstream without affecting filter performance. DuraVee filters are the ideal choice for installation on off-shore platforms, humid areas, or where moisture is often present.

Corrosion Resistant Components

The plastic and aluminum components are corrosion resistant over the life of the filter. The filter contains no metal components that could produce rust, and flake off during the service life.

Light Weight Header and Support Frames

Plastic and aluminum components result in a light weight filter in spite of the large amount of media contained in the product.

Comprehensive Testing

Extensive use is made of the ASHRAE test facilities in Louisville, Kentucky. Filters from the production line are also regularly tested by independent test labs to validate the specifications; a further guarantee for quality.

Quality Assurance Program

The Quality Assurance Program for DuraVee filters has been incorporated as an integral part of the manufacturing process. From raw materials to finished product, AAF quality checks ensure consistent and strict adherence to specifications